BCAM, Vicomtech and Egile’s innovative collaboration boosts gerotor pump efficiency by 16%

In a landmark achievement, a collaboration between BCAM, Vicomtech, and Egile has resulted in a significant enhancement in the efficiency of gerotor pumps.

10.07.2024

In a landmark achievement, a collaboration between BCAM, Vicomtech, and Egile has resulted in a significant enhancement in the efficiency of gerotor pumps.

This collaboration has also resulted in a paper, by J. C. Pareja-Corcho; M. Barton; A. Pedrera-Busselo; D. Mejia-Parra; A. Moreno; and J. Posada under the title ‘On shape design and optimization of gerotor pumps’, accepted at the SGP conference, detailing the development of an innovative algorithm to optimize the design of gerotor pumps.

The joint effort has successfully increased the flowrate of an existing gerotor pump by 16%, all while maintaining the same material usage for its manufacturing.

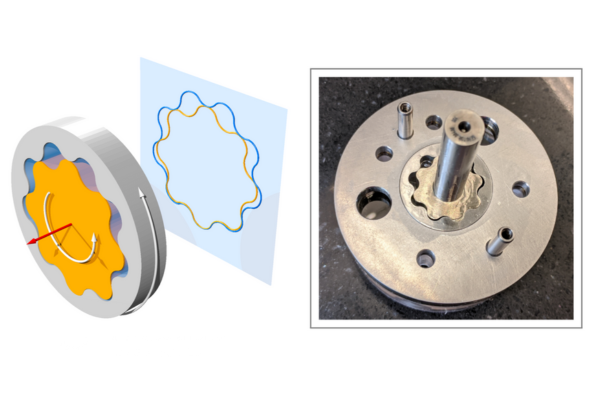

Gerotor pumps, crucial components in various fluid transfer systems, operate with two interlocking rotational parts that move fluid parallel to their axes. Despite their widespread use, finding the optimal shape for maximum fluid flow within material constraints has long been a complex challenge.

Addressing this, the collaborative team developed a novel algorithm to optimize the design of gerotor pumps. This algorithm efficiently constructs the envelope of the interior component and then optimizes it to maximize efficiency. Their approach not only enhances performance but also ensures the pump can be produced using the same amount of material as traditional designs.

"Our new optimization pipeline allows us to quickly design and optimize shapes, and consequently performance, of gerotor pumps" said Michael Barton, (Group Leader, Ikerbasque Research Associate - Mathematical Design, Modelling and Simulations line), "our simulation results are very promising as we have managed to increase the flowrate of an existing, widely used rotor by 16%. So far, we have only a plastic prototype, the next step is to manufacture a metal pump and validate these results using physical experiments."

The team applied their algorithm on a benchmark gerotor, achieving the substantial improvement in its performance. Additionally, the algorithm allowed them to study the impact of the number of teeth on the gerotor's cavity area, providing deeper insights into the design dynamics.

This development holds significant promise for industries relying on fluid transfer systems, including automotive, aerospace, and industrial machinery. The improved gerotor pumps not only enhance operational efficiency but also represent a major step forward in pump design innovation.

This successful collaboration highlights a pivotal advancement in gerotor pump technology, setting the stage for further innovations in the field.

"The applied algorithm makes use of the specific conditions of the geometry and kinematics of the gerotor pumps to efficiently and quickly generate the fast design. This efficiency and speed allows us to tackle complex problems such as shape optimisation without a large computational cost. This philosophy is in line with the rapid prototyping and design flow that Vicomtech hasdeveloped with Egile in previous collaborations", says the Vicomtech team involved in the project.

This project exemplifies perfect technological transfer, showcasing how scientific research can directly impact industry practices. By merging theoretical insights with practical applications, the collaboration between BCAM, Vicomtech, and Egile transformed cutting-edge computational techniques into tangible improvements in industrial pump design. This synergy between research and industry not only accelerates innovation but also ensures that technological advancements are swiftly and effectively implemented in real-world applications, driving progress across sectors.